Item available in 20 variants:

Price and stock visible after login

Description

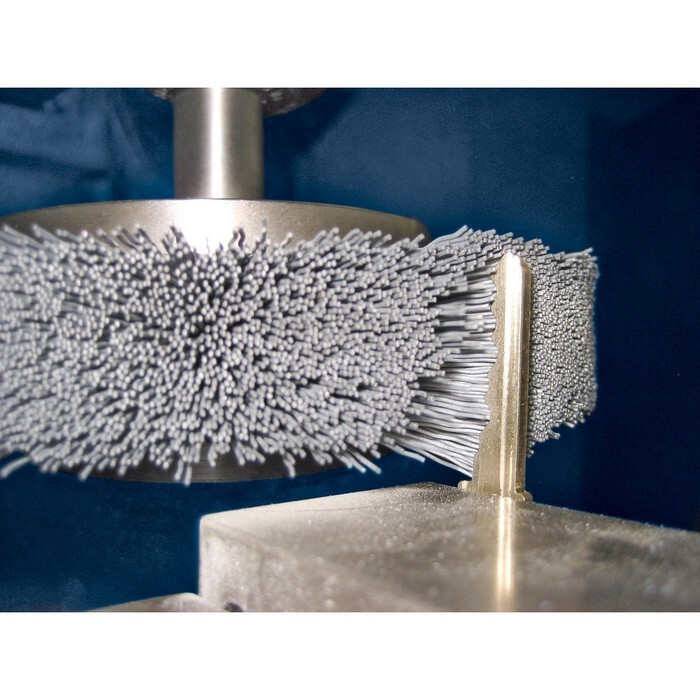

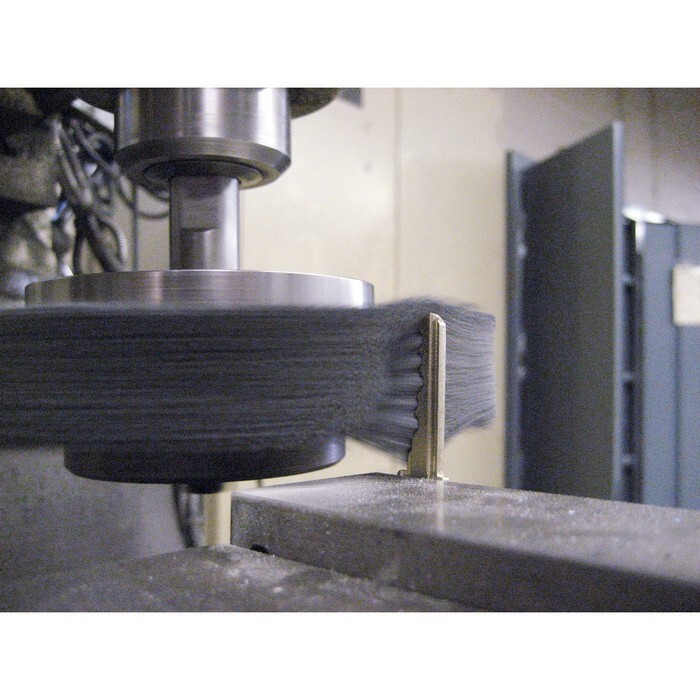

Particularly aggressive brush. Its plastic filament makes this product particularly suitable for deburring complicated components such as cylinder heads or gear toothing, as well as for working on surfaces. Developed specially for industrial use. Composite brushes from PFERD have been specifically developed for industrial, automated use. They are suitable for a variety of applications and their variable clamping options mean that they can be used on many different drive systems. This offers the advantage that the workpiece can be produced and finished on the same machine. As a result, labour-intensive, manual work is reduced and reproducible results are achieved with short cycle times. For efficient use, numerous application parameters such as the processing time and feed rate must be coordinated with each other and a suitable brush must be selected. Brushes with silicon carbide (SiC) are particularly well suited to deburring work and surface improvement. Rectangular filament [REC] is suited to applications that place particular demands on the aggressiveness of the brush. The larger cross-section of the filaments means that these are more stiff than round filaments and provide a greater contact area with the workpiece. Plastic filament withstands temperatures up to 220 °C.

Attributes

Bristle material

Silicon carbide (SiC)

Grit size

80

Holder system

Drill hole

Installation width

25 mm

Length, trim

32 mm

Max. RPM

3600 RPM

RPM, max.

3600 RPM

RPM, opt. from

900 RPM

RPM, opt. to

1500 RPM

Series

byly_RBUP_SIC_7918

Width metric

25 mm

Ø Drill

50.8 mm

Ø External metric

150 mm

Ø Trimming material

1.14 mm